Sharing basic knowledge of plastic injection

(1) Introduction to special terms for plastic injection:

Finished product: parts.

Runner: The path through which the material passes when it is injected into the product.

Gate: also called the inlet gate, refers to the surface of the runner that contacts the product.

PL surface: parting surface

CAV number: number of mold cavities

Mold: A prop used to inject finished products, divided into male mold and female mold, which can also be called the movable side and the fixed side.

Burrs: formed by material flowing out from the PL surface of the mold or the fitting gap of the insert.

Silver bars: Silver-white stripes produced at irregular locations on the surface of the part along the flow direction of the material.

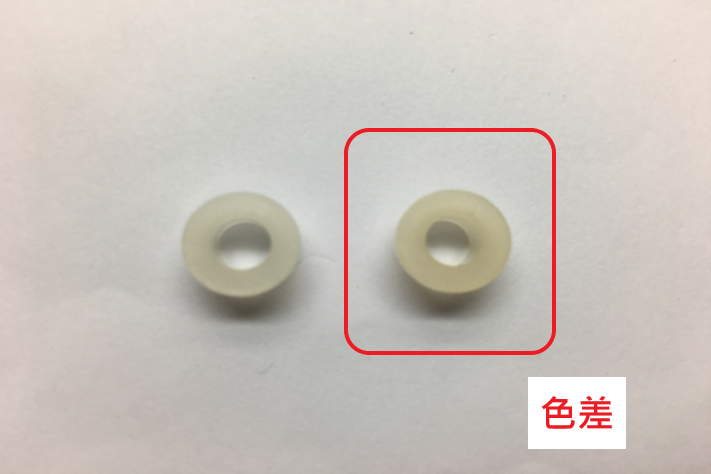

Color: The surface color of the parts is different or the thickness of the parts is greatly different.

Unfilled mold: The product is not fully filled to 100%.

Oil stain: Oil attached to parts can be eliminated after slight wiping.

Scars: Including scratches, abrasions, strains, etc., which are adverse phenomena caused by parts during transportation or due to mold relationships.

Depression: The depression that occurs on the surface of a part after it is completely filled but is not yet 100% full.

Bonding line: The fine line marks on the surface caused by the material flow diverging and then joining.

Deformation: the difference between positive and negative warping values in the curve on the same plane or radian.

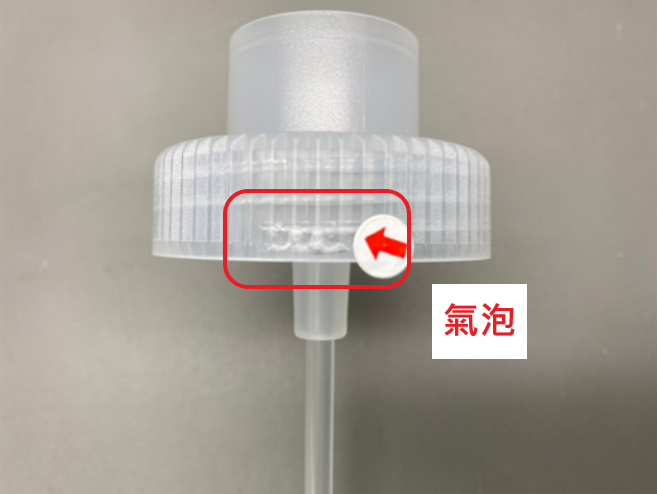

Bubbles: Transparent parts are more visible because of the air layer created inside.

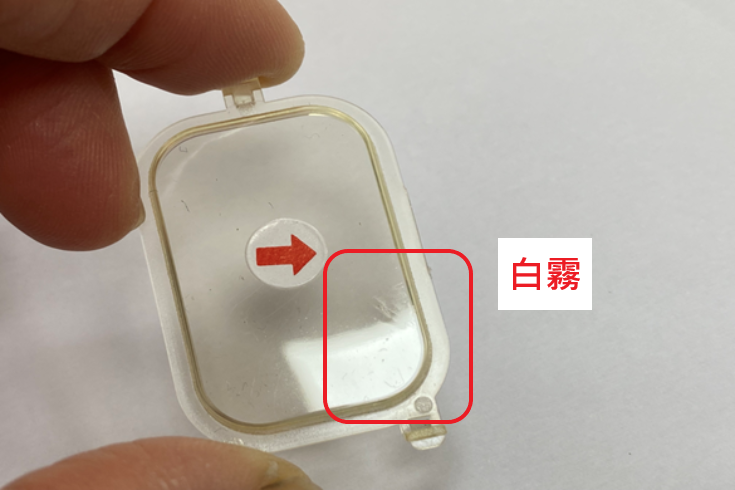

Surface accuracy: refers to the uneven surface of high-brightness or transparent parts. Look directly at the fluorescent lamp or look parallel with the reflection of the fluorescent lamp.

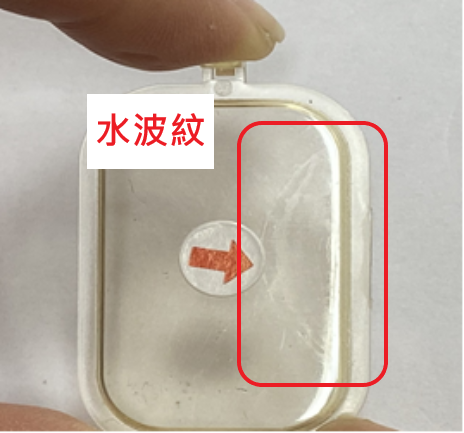

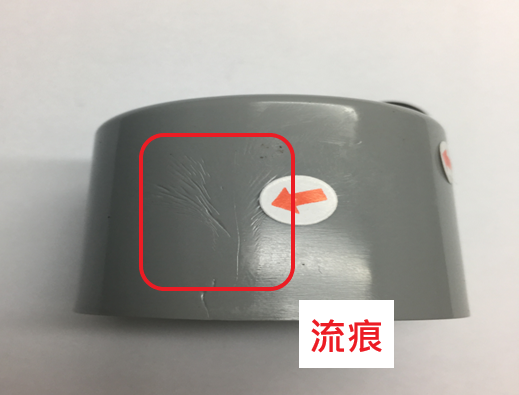

Flow marks: Ring-shaped or wavy, flowing patterns (slow injection) spray marks appear on the surface of the part.

Secondary material: also known as recycled material, refers to materials that have been produced and then crushed or extracted.

Ejection mark: Ejection mark refers to the ejection mark when the part is ejected from the mold with an ejection pin.

Ejection white: The ejection white mark refers to the mark caused by the forced separation of the part during ejection. This mark exists on the appearance surface of the part.

Year and month stamp: production date of finished product.

Scorch: Black scorch marks left on parts (hot gas decomposes after being compressed).

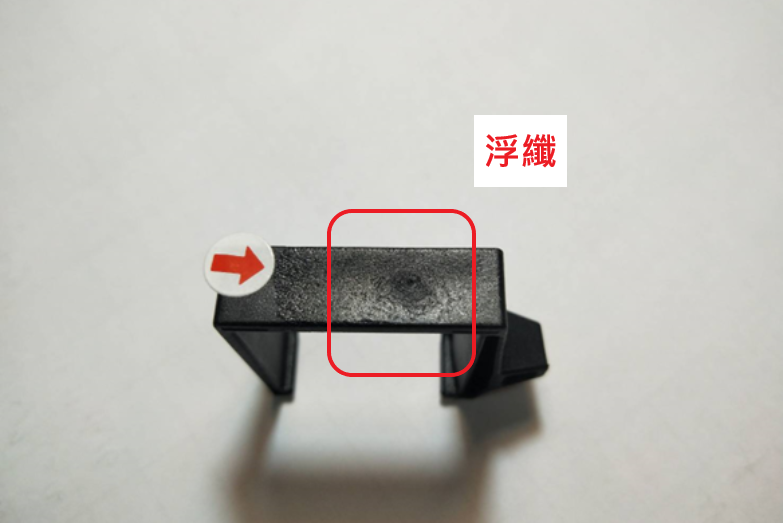

Floating fiber: The glass fibers of the material float out of the surface of the finished product (glass fiber GF).

(2) Classification of forming defects

Insufficient filling, dents, yellowing, black streaks, matte surfaces, silver streaks, flow marks, fusion marks, foreign matter

Uneven color, stains, scratches, lack of transparency, rough edges, poor size, warping, deformation

(3) Causes and improvement methods of poor forming

1) Insufficient filling

This is a phenomenon in which part of the molded product is missing, and is a representative example of molding failure.

Underfilling is the result of molten plastic not flowing into every corner of the molded product. The main reasons are as follows:

The first reason is the so-called insufficient L/t. L/t is the ratio when the plastic flow distance is L and the thickness of the molded product is t.

Improve methods:

Improve the fluidity of plastic, that is, choose plastic with good fluidity and increase the temperature of the heating barrel.

In order to make the molten plastic flow into each end of the mold as quickly as possible, the resistance of the mold, runner, and gate should be minimized, especially the resistance of the gate.

The second reason is due to the difference in resistance from the runner to the gate, resulting in a gap in the pressure of the molten plastic at the gate.

Insufficient filling for this reason often occurs in multi-cavity molds. Therefore, the distance from the multi-cavity mold to the gate must be equal.

In principle, the molds for pairs of mold cavities should be of similar size and weight. The modification method is to enlarge the gate of the mold cavity where insufficient filling occurs.

If it is an injection molding machine with multi-stage injection function, the injection speed can be reduced before passing through the gate.

By speeding up the injection speed after passing through the gate, insufficient filling can be improved.

The third reason is the residual gas in the mold. To avoid this underfilling, the mold closing line,

There must be a gap around the ejection pin or insert to allow air to escape. At the same time, the injection speed should be slowed down at the end of the injection process.

Allow sufficient time for the air to escape.

2) Depression

Among the defects of injection molded products, dents are a defect with a high probability of occurrence.

During the injection molding process, the injected molten plastic solidifies when it comes into contact with the mold surface.

At this time, because the density of the solidified plastic and the molten plastic are different, its thickness is smaller than the mold gap, and its degree is proportional to the shrinkage rate.

The thickness of the thick part and the thin part of the molded product are reduced to different degrees, and the curing time is also different, so dents are prone to occur.

Second, the molten plastic has to withstand the compression force, and the thick part in front of the thin part no longer bears pressure after the thin part solidifies.

Then its degree of shrinkage will be greater than that of the thinner part, so a depression will occur. In addition, crystalline plastics with relatively large shrinkage rates are also more prone to dents.

Methods to prevent dents: Continue to maintain pressure during molding until the molten plastic is completely solidified. The holding pressure should be larger in the early stages of solidification.

The holding pressure in the later stage needs to be reduced. In terms of the mold, locating the gate in the thick part of the molded product and enlarging the gate are all ways to prevent dents.

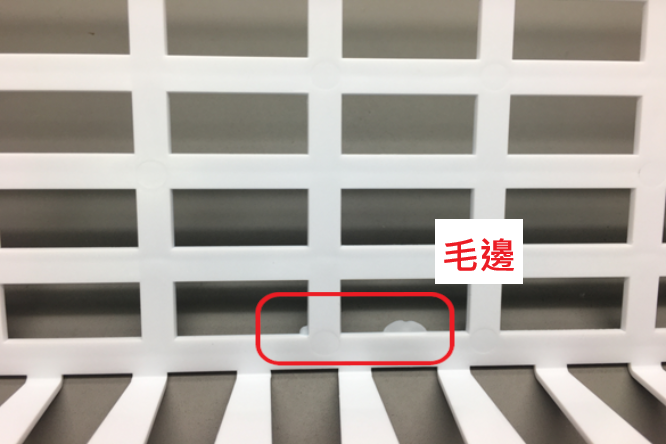

3) burrs

When the mold is being formed, due to poor sealing, the molten plastic enters the mold cavity and leaks, which adheres to the parts after cooling.

That's what we mean by rough edges. According to the structure of the mold, the burrs are usually divided into: broken burrs, rubbed burrs, matching burrs, and molded burrs.

PL surface burrs, etc. The main reasons for burrs are as follows: insufficient clamping force, broken PL surface or inlet of the mold itself,

The molding condition setting pressure is too high, the injection rate is too fast, the molding material temperature is set too high (tube temperature) or

If the residence time is too long, the material will decompose excessively, foreign matter will adhere to the PL surface or between the inlets, and the mold clamping will not be tight, etc.

4) Burnt

The main reason for the scorching phenomenon is the presence of air in the mold. When air is compressed, it releases heat, causing the plastic to burn.

In molding, if the burnt part is at the end of the plastic process, the injection speed of the last stage can be reduced.

If the fusion mark is burned, the speed of the molten plastic flowing through the fusion mark can be reduced; a small groove can be formed on the mold to allow air to escape.

5) black line

This is the phenomenon where a black line appears on the molded product from the gate to the direction of plastic flow. It is the part where the plastic decomposes and turns black.

Produced during mixing during molding. This decomposition is mainly caused by the high temperature of the plastic, but the decomposition of the added flame retardant is also one of the reasons.

matte

The surface gloss of the product is poor. Most of the reasons are caused by excessive use of release agent or insufficient polishing or scratching of the mold.

Silver traces

On the surface of the product, silvery white stripes appear along the direction of plastic flow. This is the moisture or volatiles present in the molten plastic,

What is in the liquid state due to compression in the injection machine evaporates into gas due to the decrease in pressure after extrusion from the nozzle.

When the plastic solidifies, it becomes fine bubbles. Therefore, completely removing moisture from raw materials or preventing raw materials from decomposing can prevent this defect.

Flow marks

The surface of the product has a grid-like pattern centered on the gate. The main reason for this phenomenon is that when the injected plastic solidifies,

Sometimes it comes into contact with the mold, sometimes it leaves it. The specific method to prevent defects is to slow down the injection speed or increase the plastic temperature and mold temperature.

It is also an effective method to slow down the injection speed in parts prone to flow marks and then increase the injection speed to a level where insufficient filling does not occur.

Fusion line, combined pouring line

This phenomenon occurs when the molded product has holes, or when the molded product has a thin part in the center of the thick part, or when two or more gates are used for molding.

When molten plastic flows in the injection molding machine, the temperature at the tip of the plastic flow inevitably drops slightly.

Therefore, marks that do not fuse with each other will be formed at the meeting point of the plastics, which are fusion marks.

The response method is to use plastic with good fluidity and increase the temperature of the plastic in areas where fusion marks appear to prevent air from blocking the flow of the plastic.

In addition, poor exhaust is also one of the causes of fusion marks.

jet marks

Earthworm-shaped streaks starting from the gate appear on the molding surface. This is when the plastic through the gate contacts the mold surface in a strip shape and solidifies.

It is produced by fusing with subsequent injection plastic. This is a defect that only occurs in side gate molds where the plastic flows out of the gate in a band shape. It can also occur in overlapping gates.

The occurrence of this defect can be improved when molding with pinhole gates, submersible gates or film gates.

foreign body

This is a phenomenon caused by the incorporation of foreign matter. It usually occurs when the cleaning operation is insufficient or foreign matter is present in the recycled product. However, it can also occur when the injection molding machine itself is damaged.

Uneven gloss

This is a phenomenon in which the surface gloss of a molded product is uneven and some parts have different gloss. This phenomenon is likely to occur when the mold temperature is too low, the mold is unevenly ground, or too much release agent is used.

abrasions

This is a phenomenon where the surface of a molded product is scratched by the mold, leaving scratches.

Negligence in mold making or plating, or fine lines forming in areas with small slopes resulting in a reverse slope opposite to the ejection direction of the molded product.

Bruises may occur easily. However, if there are not enough ejector pins, or if the ejector pins are biased toward one side of the molded product, scratches may also occur when demolding is not smooth and a reverse slope is formed.